Penske Racing Shocks specializes in CNC manufacturing solutions for common shock absorber components. It’s our goal and focus to produce high-quality parts that are not only highly repeatable but perform in the toughest conditions. Our equipment, which includes Mazak, Okuma, Tsugami, HAAS, and REM, gives us the capacity and ability to produce a wide range of applications. We specialize in most steel and aluminum applications. Most tolerances are typically +/-.0005” with first article and production inspections performed routinely to ensure optimum repeatability and low scrap. Ultimately this leads to lower production costs.

Products

- Solid or Drilled Steel Shafts

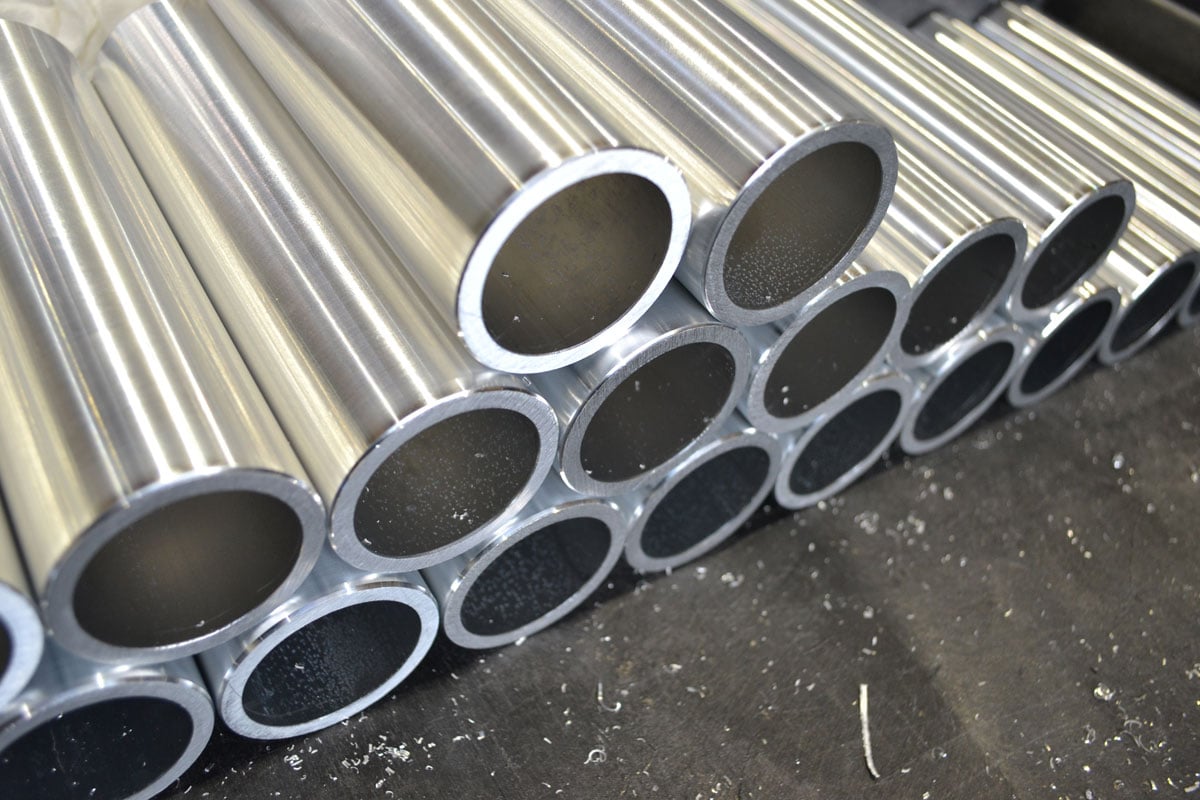

- Aluminum and Steel Tubes

- Aluminum Pistons

- Custom Designs Available

- Mounting Ends

- Body Caps and Eyelets

- Equipment

- MAZAK HQR

- MAZAK Integrex

- MAZAK QT

- TSUGAMI M08SY

- Okuma Genos L3000

- Behringer HBE Automated Saw

Start to Finish Solutions

When you pair our Custom Projects group with our manufacturing, we can supply a project from start to finish. Our group of engineers will work with you to bring your idea to reality. From initial designs to FEA, final drawings, to machining and even assembly, Penske Racing Shocks can be your one-stop shop.

Customer Commitment

The business of racing is one where a tenth of a second can be the difference between winning and losing. We take that mindset when it comes to all of our customers. Whether you’re preparing for the Indy500 or you’re just looking for quality parts in a realistic timeframe, Penske Shocks is here to help.